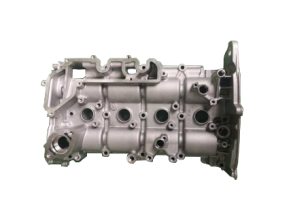

As injection molding technology can process products with complex shape, accurate size or with inserts, and its application range extends from the original plastic products field to automobile parts and other aspects.

In terms of the basic process, the plastic is extruded and heated by the screw of the injection molding machine, and becomes a molten and flowing melt. Driven by the screw, the plastic melt enters the mold cavity through the nozzle, the main channel, the shunt channel and the gate of the injection molding machine, forming products with certain shape and size.

In the injection molding process, the pressure at the nozzle of the injection molding machine is the highest to overcome the flow resistance in the whole process of the melt. After that, the pressure gradually decreases along the flow length to the front end of the melt. If the internal exhaust of the die cavity is good, the final pressure at the front end of the melt is atmospheric pressure.

Of course, in order to ensure the normal development of the injection molding process, we need to control the temperature, pressure and corresponding action time that affect the plasticizing flow and cooling.

The above is the basic content of the whole injection molding process and the basic points for attention. After this introduction, do you have a new understanding of the injection molding process?

Contact person: Mr. Wang

Tel: 0512-52972252

Email: W wang@szypco.com

website: www.szypco.com

Address: No.10 WengZhuang Road, Shanghu Town, Changshu, Suzhou, Jiangsu Province