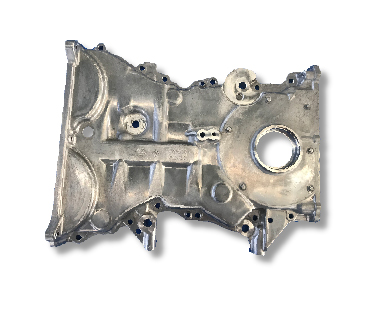

Aluminum die casting is a kind of common pressure casting parts. The aluminum and aluminum alloy heated to liquid state are poured into the material mouth by using the die casting machine with the casting die installed, and the parts are made by die casting machine. After die casting aluminum die casting can make a variety of complex shapes, but also has a high precision and finish, which can not only save power and metal materials, but also save bad labor costs. Let's discuss with the die casting manufacturer about the selection of parting surface of aluminum die casting. The contact surface between moving and shaping of die casting die is usually called parting surface. The parting surface is determined by the parting line of the die casting. The joint surface perpendicular to the direction of clamping force on the die is the basic parting surface. Generally, there is only one parting surface in the die casting mold. Sometimes, due to the complexity of the casting, there can be two parting surfaces The above auxiliary parting surface.

According to the shape of parting surface, the parting surface of die casting mold can be divided into four types: straight, inclined, stepped and curved. The straight parting surface is simple in structure and easy to make, so it is widely used. For the stepped parting surface, the gating system is generally set on one of the step surfaces, and the overflow system is set on the other step surface, so as to facilitate the filling and exhaust of molten metal.

There are many factors that need to be considered in determining the parting surface. Therefore, in selecting the parting surface, in addition to the structural characteristics of aluminum die castings and the arrangement of gating system. The processing technology and assembly process of aluminum die casting die and the demoulding conditions of die casting parts should be considered and determined as a whole. The determination principle of parting surface is as follows:

1. When opening the mold, the casting remains in the moving mold and is easy to take out from the mold cavity.

2. The parts with different axial degrees and high dimensional accuracy requirements should be set in the same half die as far as possible.

3. The parting surface is generally not set on the surface with high quality requirements.

4. The setting of parting surface should be conducive to setting up gating system, eliminating burr, flash, gate, etc., and painting.

5. The setting of parting surface should simplify the structure of aluminum die casting as much as possible, and the casting properties of the alloy should be fully considered.

Aluminum die casting plays a very important role in the current industry. It has a very wide range of uses in many industries. With the continuous development of society, people's living demand is also increasing. When operating, the demand for aluminum die casting technology is also increasing.

Main advantages of aluminum die casting

1. Aluminum die casting is beautiful in appearance and light in weight. It can be easily transported in the process of operation. It is also a great advantage to use it in automobile.

2. The density of aluminum alloy is obviously less than that of cast iron and cast steel, but its strength and properties are much higher. Therefore, under the same load weight, using aluminum die casting can reduce the structure weight.

3. For the surface of aluminum alloy, its surface gloss is very good, and the casting performance is also good.

The mechanical properties and tensile strength of aluminum die castings have great resistance when they are made. To a certain extent, their elongation is a measure of material brittleness and plasticity. Hardness is the resistance of material surface to plastic deformation caused by hard material pressing or friction.

The working temperature and humidity of aluminum die casting, the medium and air tightness of workpiece contact, the accuracy and dimensional stability of the whole product are required.

The accuracy of aluminum die casting profile and surface roughness will directly affect the working efficiency of pump and hydraulic system, energy consumption and development of cavitation. The strength and resistance to chilling and heat shock of cylinder block, cylinder head, cylinder liner, piston ring and exhaust pipe of internal combustion engine directly affect the working life of engine.

Sand mold casting is preferred for aluminum die castings because of its low cost, simple production process and short production cycle compared with other casting methods. When the wet mold can not meet the requirements, then consider using clay sand surface dry sand mold, dry sand mold or other sand mold. The casting methods of aluminum castings should be compatible with the production batch. Low pressure casting, die casting, centrifugal casting and other casting methods are only suitable for mass production because of the high cost of equipment and mold. The cast aluminum parts can be single casting or mass production.

Contact person: Mr. Wang

Tel: 0512-52972252

Email: W wang@szypco.com

website: www.szypco.com

Address: No.10 WengZhuang Road, Shanghu Town, Changshu, Suzhou, Jiangsu Province